Casting with CA6NM alloy, serial processing, polishing method

Materials are purified at melting furnaces.

Critical bearing connectors for the construction industry

Single crystal turbine blades

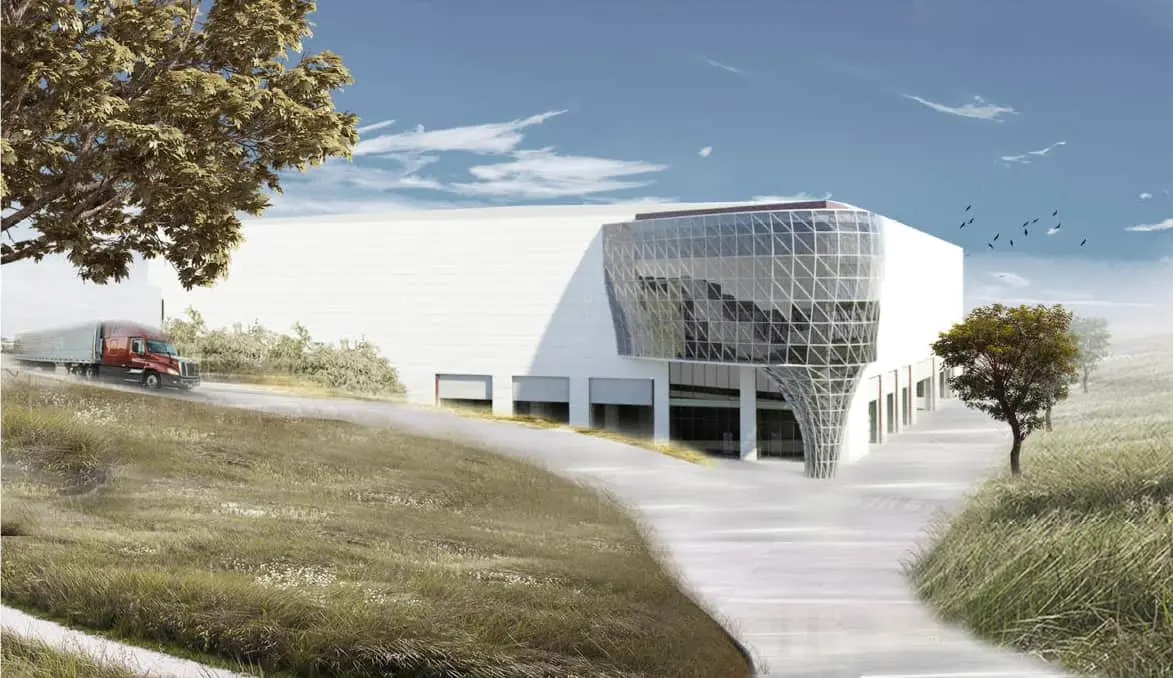

Yalova Organized Industrial Zone

Casting with CA6NM alloy, serial processing, polishing method

Materials are purified at melting furnaces.

Critical bearing connectors for the construction industry

Single crystal turbine blades

Yalova Organized Industrial Zone

MARKETS

CONSTRUCTION FITTINGS

A critical industry for the construction economy. The past impact of the industry considered as a driving force behind employment and the economy can lead to erroneous assumptions about the future…

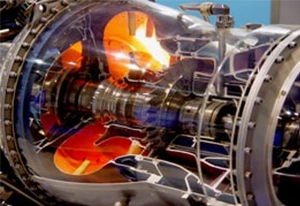

AVIATION–TURBINES

Global aviation technology is in the “single crystal” era. The system exceeds the limits of crystal, ensuring safer aircraft with a longer useful life…

DEFENSE INDUSTRY–ARMOR

The defense industry naturally needs long-lasting equipment resistant to all kinds of harsh conditions. Firmametal ensures the required level of endurance using a special method of refining…

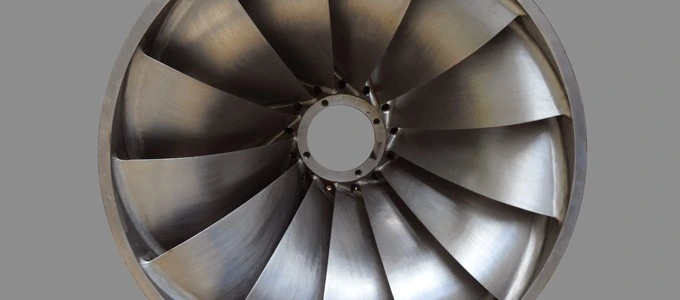

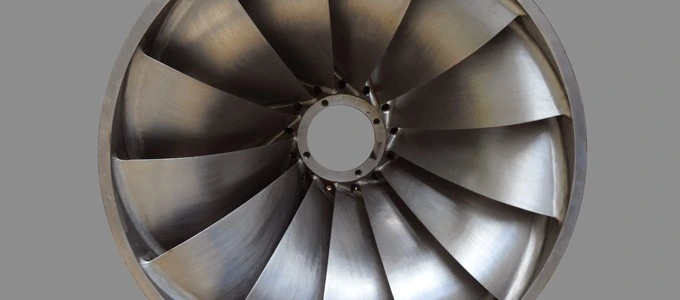

ENERGY–HIDROELECTRIC

Energy is a significant part of the economy and we are proud of our investment in this area. However, the materials required for this investment are mostly imported, constituting a significant area of dependence…

CUTTING-EDGE MACHINERY INDUSTRY

Expanding its works in the machine industry, Firmametal sets its goals on designing high added-value products to become the high-technology production and application partner of leading global manufacturers.

CONSTRUCTION FITTINGS

A critical industry for the construction economy. The past impact of the industry considered as a driving force behind employment and the economy can lead to erroneous assumptions about the future…

AVIATION–TURBINES

Global aviation technology is in the “single crystal” era. The system exceeds the limits of crystal, ensuring safer aircraft with a longer useful life…

DEFENSE INDUSTRY–ARMOR

The defense industry naturally needs long-lasting equipment resistant to all kinds of harsh conditions. Firmametal ensures the required level of endurance using a special method of refining…

ENERGY–HIDROELECTRIC

Energy is a significant part of the economy and we are proud of our investment in this area. However, the materials required for this investment are mostly imported, constituting a significant area of dependence…

CUTTING-EDGE MACHINERY INDUSTRY

Expanding its works in the machine industry, Firmametal sets its goals on designing high added-value products to become the high-technology production and application partner of leading global manufacturers.

WHY FİRMAMETAL?

PRODUCTION

Firmametal undertakes customized, customer-specific production for every product it manufactures. The products can neither be found on the market, nor can be imitated due to their material structure designed using cutting-edge technology and advanced engineering. Firmametal conducts manufacturing operations in five main fields: casting; forging; precision machining; stamping and welding. The company also utilizes injection die-casting methodologies.

PRODUCT DEVELOPMENT

With its expertise and experience in materials science and technologies, Firmametal makes significant R&D efforts to turn all kinds of materials that require precision processing into final products. The products processed using cutting-edge technologies are designed and manufactured as per our customers’ demands and requirements.

WORKFLOW AND PROCESSES

Firmametal evaluates each requested product in light of its collected material sciences and technologies expertise. Commissions professional firms from group companies to implement the development phase. In this process, the mother company, Firmametal, and each other organization in the overall “ecosystem” act together as a team. Firmametal is the ultimately liable party for all processes until the planned product has successfully been converted into a manufactured high quality good.

QUALITY AND COMMITMENT

When extremely sensitive products are designed, quality, safety and control are the most important phases of the work processes. Firmametal takes the entire responsibility for these stages, ensuring that the product is manufactured according to the appropriate quality standards. Quality, safety and control are ensured by Firmametal or by an external certification body, in accordance with the standards and certification process of the requesting company.

PRODUCTION

Firmametal undertakes customized, customer-specific production for every product it manufactures. The products can neither be found on the market, nor can be imitated due to their material structure designed using cutting-edge technology and advanced engineering. Firmametal conducts manufacturing operations in five main fields: casting; forging; precision machining; stamping and welding. The company also utilizes injection die-casting methodologies.

PRODUCT DEVELOPMENT

With its expertise and experience in materials science and technologies, Firmametal makes significant R&D efforts to turn all kinds of materials that require precision processing into final products. The products processed using cutting-edge technologies are designed and manufactured as per our customers’ demands and requirements.

WORKFLOW AND PROCESSES

Firmametal evaluates each requested product in light of its collected material sciences and technologies expertise. Commissions professional firms from group companies to implement the development phase. In this process, the mother company, Firmametal, and each other organization in the overall “ecosystem” act together as a team. Firmametal is the ultimately liable party for all processes until the planned product has successfully been converted into a manufactured high quality good.

QUALITY AND COMMITMENT

When extremely sensitive products are designed, quality, safety and control are the most important phases of the work processes. Firmametal takes the entire responsibility for these stages, ensuring that the product is manufactured according to the appropriate quality standards. Quality, safety and control are ensured by Firmametal or by an external certification body, in accordance with the standards and certification process of the requesting company.

Firmametal integrates latest technologies to manufacturing and business processes; products and services bear testimony to global expertise and knowledge of material science.

Firmametal integrates latest technologies to manufacturing and business processes; products and services bear testimony to global expertise and knowledge of material science.

PRODUCTION

PRODUCTION

HI-TECH CASTING

Firmametal’s hi-tech casting propriety processes consist of refining technologies and precision alloying techniques developed though extensive accumulated know-how, studies of melting techniques and associated R&D.

FORGING

Forging is the hot, warm or cold process of component forming utilizing only an applied force. Forging is completely different from casting as forging strengthens textures by deforming the existing atoms’ spatial relationships.

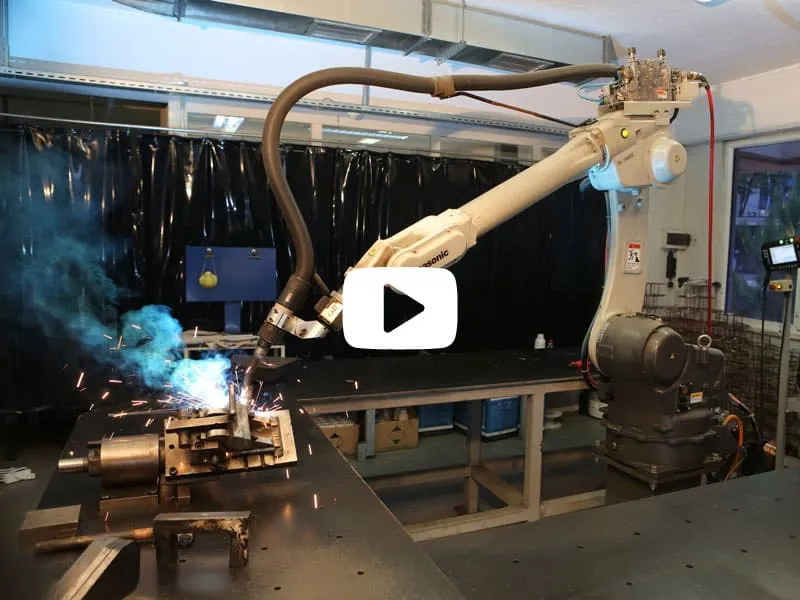

WELDING CONSTRUCTION

Welding process is the combining of materials in the welded area though…

PRECISION SHEET METAL STAMPING

Precision stamping requires sheet metal to be cut to a…

PRECISION MACHINING

Firmametal was able to respond to a range of production demands…

HI-TECH CASTING

Firmametal’s hi-tech casting propriety processes consist of refining technologies and precision alloying techniques developed though extensive accumulated know-how, studies of melting techniques and associated R&D.

FORGING

Forging is the hot, warm or cold process of component forming utilizing only an applied force. Forging is completely different from casting as forging strengthens textures by deforming the existing atoms’ spatial relationships.

WELDING CONSTRUCTION

Welding process is the combining of materials in the welded area though…

PRECISION SHEET METAL STAMPING

Precision stamping requires sheet metal to be cut to a…

PRECISION MACHINING

Firmametal was able to respond to a range of production demands…

Creative Solutions