Hydroelectric Power Plants and the Characteristics of Francis Turbines

The Francis turbine is a type of turbine that can be used in medium and high head conditions. It is among the most frequently used reaction turbines in medium or large-scale hydroelectric power plants. Francis turbines, which have multiple components such as blades, casings, and wheels, can be used in falls ranging from as low as 2 meters to as high as 300 meters. You can easily find what you’re curious about regarding these types of turbines, which have a wide variety of application areas, in our content.

What is a Francis Turbine, and What Does it Do?

First, when looking at what a Francis turbine is; these are reaction turbines that can be used in hydroelectric power plants of different sizes. In this aspect, water enters the turbine in an axial direction from the surroundings towards the center and exits in a radical manner in Francis turbines, which are preferred in many applications. The reaction turbines, which these devices are part of, take in high-energy liquid and reveal its momentum. In this aspect, they are among the types of reaction turbines, just like Kaplan turbines. Francis turbines, which use both the pressure and the kinetic energy of water, can thus work across a broad flow range.Additionally, these turbines can work equally well when positioned horizontally as well as when directed vertically. Francis turbines are the most frequently used turbines in hydroelectric power plants. These turbines can offer efficiencies up to 95% thanks to their design. However, this is only possible under optimum conditions. Francis turbines are the first hydraulic turbines with a radial entrance, designed by the American scientist James Francis.

About James Francis, the Inventor of the Francis Turbine

James Francis (1815 – 1892) was an engineer born in England. He began his engineering career at the age of seven, working as an apprentice to his father. In 1848, Francis and another engineer, Uriah A. Boyden, successfully developed the turbine now known as the Francis turbine. After examining Boyden’s turbine, Francis managed to redesign it to increase its efficiency. Thus, Francis achieved a remarkable efficiency rate of 88%.Working Principle of the Francis Turbine In these types of reaction turbines, water enters axially from the surroundings of the turbine towards the central point. Then, it exits in a radical manner. The water passing through the Francis turbine loses pressure but remains at roughly the same speed. Therefore, it is considered a reaction turbine. After entering the turbine, the water always flows inward, towards the center. It also has a fairly simple design. A flat, circular plate has rotating shafts sitting vertically on this plate. Curved blades are located on the plate. The blades, known as guide vanes, are stationary and mounted on the interior surface. These blades serve the purpose of directing the water at the appropriate angle.

Components of the Francis Turbine Spiral Casing

The Francis turbine has a spiral casing that ensures water is evenly distributed around the turbine. These casings help the water to flow smoothly into the turbine, thus increasing the turbine’s efficiency.

Guide Vanes: Just like in Kaplan turbines, Francis turbines have guide vanes. These vanes, located inside the spiral casing, control the direction and speed of the flow before it is directed to the wheel. The vanes open and close to adjust the turbine’s output power.Turbine

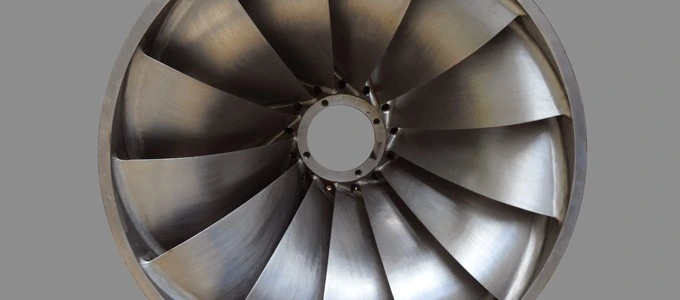

Wheel (Runner): The turbine wheel is like the heart of the Francis turbine. These wheels convert the energy of water into mechanical energy. Water hits the blades of the wheel, initiating its rotational movement.

Draft Tube: The water entering the wheel moves to the exit step. Then, it is removed from the turbine through the draft tube. The draft tube has the task of raising the water’s pressure to atmospheric pressure. This maximizes the use of the water’s kinetic energy and increases the water’s entry speed to the turbine. Generator: Lastly, Francis turbines have a generator. Through this component, the rotation of the turbine wheel is converted into electrical energy.

Applications of Francis Turbines

Francis turbines are frequently used in hydroelectric power plants due to their high efficiency and wide operating range. Their ability to operate in medium and high head conditions makes Francis turbines ideal for hydroelectric projects. In these plants, high-pressure water enters the turbine and is directed to the blades at optimal angles.

Advantages & Disadvantages

These reaction turbines offer a wide operating range, compact and simple design, high durability, and longevity, making them quite advantageous. These features make them highly efficient for many hydroelectric projects. Among their disadvantages are high installation costs, more complicated manufacturing processes, the risk of cavitation, and environmental impacts.