What is Cryogenic Steel?

Cryogenic steel offers superior endurance even at very low temperatures. Its outstanding durability and toughness make it a prominent material in sectors such as maritime and defense industries. Having various types helps find the cryogenic steel suitable for specific needs. In our content, you can find answers to questions like what is a cryogenic process and what is cryogenic steel used for.

What is the Cryogenic Process?

First, looking at what cryogenic means; this concept is a term in physics. It refers to the production and processes at very low temperatures. The origin of the word comes from the Greek words “kryos,” meaning “cold,” and “genic,” meaning “to produce.” With the cryogenic process, it’s possible to enhance the thermal treatment by going down to temperatures as low as -196°C. As a result, materials processed this way can achieve high wear resistance, high toughness, and low friction on the surface.

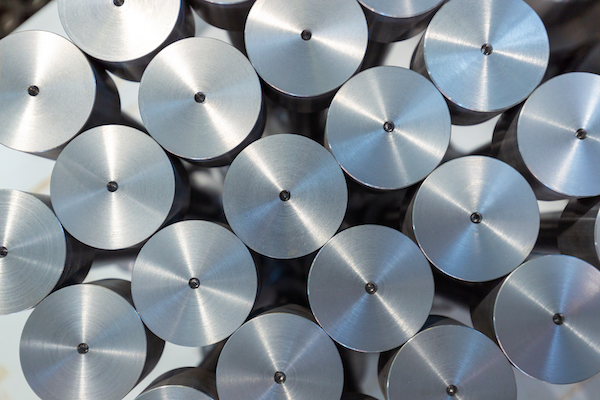

What is Cryogenic Steel?

Steels that have undergone the cryogenic process are also known as cryogenic steels. These types of steels maintain superior endurance even at very low temperatures. Moreover, due to their excellent toughness, they represent a special type of steel. Cryogenic steels, thanks to their superior properties, are ideal for critical applications such as bearing shells and railway connections. For example, ball sockets and bearing shells are very important for the maritime and defense industries. These application areas require high strength and durability. Cryogenic steels are materials that can provide this high-level endurance.

What are the Features of Cryogenic Steel?

These types of steels, especially at very low temperatures, provide top-level performance and safety. Therefore, they are often chosen materials in areas such as defense, transportation, and energy. The most prominent feature of these materials is their high strength and toughness. In addition, they have various other advantages. Below, you can review some of their outstanding features:

- High Strength and Toughness: Steel material that has undergone cryogenic treatment becomes much more durable.

- Easy Processability: Pure steels wear and tear less during the processing phase. Thus, manufacturing efficiency increases, and product quality also improves.

- Customizable Options: These types of pure steels can be customized according to the needs and application areas.

- Longevity: Due to features such as high strength and toughness, these steels are much longer-lasting.

- Safety: The risk of failure in materials made of pure steel decreases.

What is Cryogenic Steel Used For?

The cryogenic process exposes steel to extremely low temperatures. This results in a significant improvement in material performance. Its properties make cryogenic steels necessary for areas like the maritime and defense industries. In addition to the aforementioned ball sockets and bearing shells, it is also prominent in railway connections. Additionally, it is a very important material in polar regions or in the transportation of liquid gases.

Steps Applied in the Cryogenic Treatment of Steel

There are various stages related to steel undergoing cryogenic treatment. These include correct material selection, thermal treatment, mechanical tests, and many subheadings. All these steps are important in terms of selecting the right steel and processing it correctly. Below are the application steps in order.

- Material Selection: It’s necessary to choose one of the suitable steels for cryogenic processes. Steel generally offers a wide variety of materials. Therefore, choosing those that can undergo cryogenic treatment is important. Among these options are steels containing alloy elements such as niobium, vanadium, or titanium. These components typically stand out among cryogenic steels because they provide high toughness and strength at low temperatures.

- Design and Engineering: Design and engineering are methods of identifying and solving various engineering problems. It consists of many components like originality, adaptability, and product design. In this phase, the mechanical properties of the material are also very decisive. Accordingly, the field of design and engineering can be summarized in three points:

- Mechanical Properties: This is the step where mechanical properties like a material’s strength, hardness, brittleness, and toughness are considered. Accordingly, choosing the right material becomes significant.

- Thermal Treatment: One of the most important parts of the production process. It involves heating metal or another material to a certain temperature and then cooling it for hardening.

- Design Optimization: This is the stage of choosing the most suitable design among many options. It involves optimizing the dimensions, geometry, and other elements of components.

3. Manufacturing Techniques

Special methods related to the cryogenic treatment of steel come into play at this stage. It can be summarized in two items: welding – joining and processing precision:

- Welding and Joining: The welding of cryogenic steels should be done without deteriorating the properties of the material. Therefore, suitable welding methods and parameters should be selected.

- Processing Precision: Productions like ball sockets, bearing shells, and railway connections require high precision. For this, advanced manufacturing technologies such as CNC machines can be used.

4. Testing and Evaluation It is important to check whether products demonstrate the expected performance after manufacturing. Therefore, products must undergo various tests and evaluations before they are launched on the market. In cryogenic steels, these applications are under two subheadings:

- Cryogenic Tests: Performed to understand whether the steel has the expected high strength at low temperatures.

- Mechanical Tests: This is where tensile strength, impact, hardness, and brittleness tests, etc., are located. It is important to see whether the material and product meet the expected standards.